Laser-cutting technology has drastically transformed the manufacturing and fabrication industries. The efficiency and precision of laser cutting technology make it a go-to choice for various industries. It is evident that aluminum cutting has gained immense popularity.

Aluminum cutting is widely utilized in the aerospace, automotive, and construction industries because aluminum offers lightweight and corrosion-resistant properties. These features make aluminum suitable for various applications in these fields.

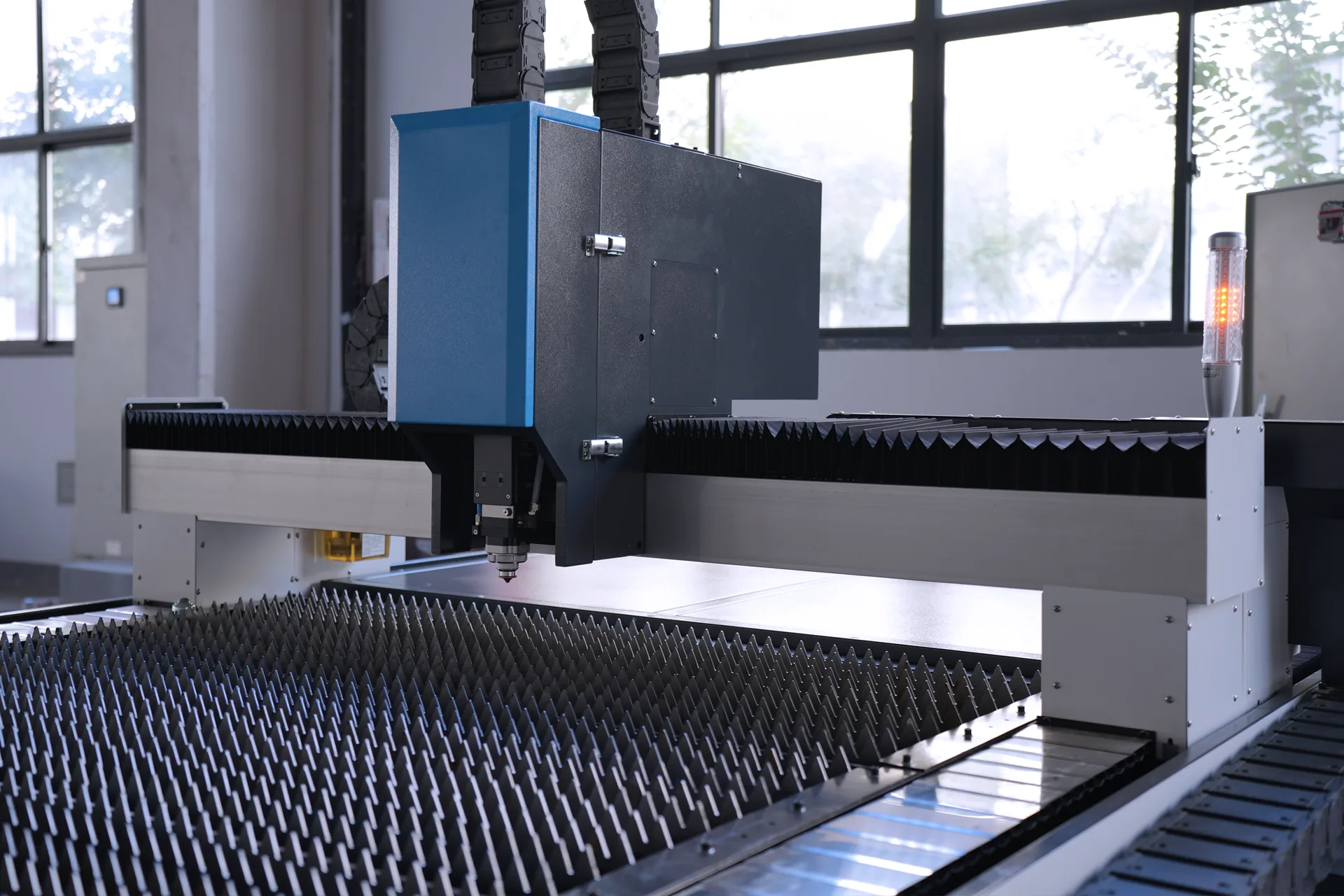

What is a CNC Laser Cutting Machine?

A CNC laser cutter is a part of a computer numerical control (CNC) machine, and it uses a more focused and high-powered laser beam to carve, mark, or cut materials.

Proper maintenance extends the life of the cutter. It also enhances the cutting quality, reduces downtime, and improves productivity.

This article will cover all important maintenance practices to keep your CNC laser cutting machine for metal in perfect condition, especially for aluminum cutting.

Regular Cleaning and Inspection

It is necessary to keep your CNC laser cutter clean and free from debris.It is indeed a crucial aspect, because, residue from cutting operations, metal shavings, and aluminum dust can accumulate within the machine over time. This may reduce its cutting accuracy and damage the laser optics or cause malfunctions.

- Laser Optics Cleaning- The lens and mirrors should be gently cleaned regularly. Dust and dirt can lead to poor cutting quality and laser power would be lost. Use lint-free wipes and cleaning solutions designed for laser optics.

- Fume Extraction System: A CNC laser cutting machine uses fume extraction systems. It is to remove smoke and particulate matter generated during cutting. Make sure the filters are cleaned and occasional replacement can help control blockages and maintain optimal airflow.

- Regular Inspection: Perform a routine inspection to look for lubrication issues and misalignment. Frequent inspections will help tackle minor issues before they become worse.

Maintain Proper Alignment

Throughout the cutting process, the laser needs to be accurate and consistent. For this, proper alignment is crucial. Misalignment can lead to poor cuts and increased energy consumption.

- Check the Beam Path: To avoid uneven cuts and laser power loss, make sure the beam path is correctly aligned.

- Adjust the Cutting Head: The cutting head must be correctly aligned to the material’s surface to get a smooth and accurate cut. Check its height and positioning.

Lubricate Moving Parts

The moving parts of a CNC laser cutter, such as rails, motors, and drives, need regular lubrication. The lubrication can help to reduce friction and thereby prevent premature damage.

- Lubrication of Rails and Bearings: Only use high-quality lubrication to ensure smooth movement.

- Grease the Gears: Give regular lubrication to the gears that move the machine’s cutting head. Metal dust and heat can wear down gears over time, slowing machine performance.

Focus on the Laser Source and Power Supply

The laser source and power supply are the soul of your CNC laser-cutting machine. These components need proper maintenance to keep up the high performance and extend the machine’s lifespan.

- Laser Power Adjustment: The laser’s power output can diminish over time. Check the power settings on your CNC laser daily and adjust them according to the material thickness and type. This is important when cutting aluminum.

- Cooling System Maintenance: A considerable amount of heat is emitted during operation, so it’s essential to maintain the cooling system. Ensure the cooling system is working correctly by checking the coolant levels daily.

Software Updates and Calibration

Hardware calibration and software updates are necessary to keep the accuracy of your CNC laser cutting machine. When working with aluminum, it requires high precision for clean, smooth edges. A properly calibrated machine ensures precise cuts in aluminum.

- Laser Calibration: When you cut metals, a small misalignment can affect the final product. So, perform frequent laser calibration to ensure the laser beam is well-focused and aligned with the material.

- Software Maintenance: Your CNC cutting machine’s operations rely on software. Ensure that the software is up-to-date. Do regular updates, so that bugs are fixed if any, and machine performance improves.

Conclusion

Whether you are using a CNC fiber laser cutter or a traditional CNC laser cutter, proper maintenance guarantees that your machine continues to offer high performance, helping your business stay competitive and efficient. Whether you’re a business looking for precision laser cutting, prototyping, or powder coating, we work closely with you to ensure every project is a win-win situation.

The Random Collective Where Curiosity Meets Creativity

The Random Collective Where Curiosity Meets Creativity